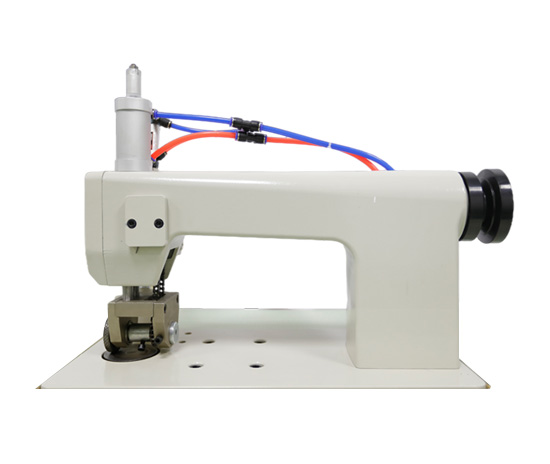

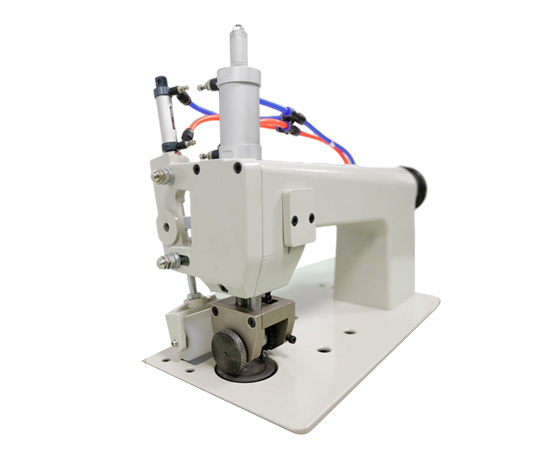

Ultrasonic sealing machine suitable for making lace clothing, ribbons, decorative products, handkerchiefs, tablecloths, curtains, bedspreads, pillowcases, quilt tents, raincoats, disposable surgical clothes and hats, non-woven masks, non-woven fabrics, etc.

1. Edge cutting: Unilateral straight line or curve cutting, and edge dissolving treatment to make the edge smooth and smooth without roughness;

2. Stitching: two or more layers of fabric are stitched together, wireless needle-free instead of sewing, and the welding strength is good;

3. Engraving hole: cut out all kinds of flower holes, and do edge melting treatment;

4. Strip cutting: single or multiple strips of the material are cut at the same time, and the edge melting treatment is no burr;

5. Molding: cutting, suturing and embossing at the same time, so that the product can be molded at one time

2. Stitching: two or more layers of fabric are stitched together, wireless needle-free instead of sewing, and the welding strength is good;

3. Engraving hole: cut out all kinds of flower holes, and do edge melting treatment;

4. Strip cutting: single or multiple strips of the material are cut at the same time, and the edge melting treatment is no burr;

5. Molding: cutting, suturing and embossing at the same time, so that the product can be molded at one time